|

| April 10, 2012 | Volume 08 Issue 14 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

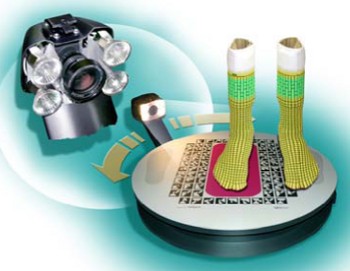

Tiny cameras make 3D foot scanner a custom fit for shoemakers

Be it running, skiing, or hiking, it's hard to do it without shoes. However, shoes have to fit properly; otherwise the result is more pain than pleasure. Custom shoes are the answer, but they are expensive. That's why most consumers settle for "good enough" when it comes to footwear.

But now German shoe company corpus.e has developed an affordable 3D foot scanner they say will change all that. Their Lightbeam scanner is lightweight, compact, and economic – on the one hand because it doesn't operate with expensive laser projection, but instead uses a special stocking, and on the other hand because it employs a USB 2.0 industrial camera from IDS instead of expensive stereo cameras.

A special, patented sock with photogrammetric markings, called the MagicalSkin stocking, is pulled over the customer's foot. Then the customer steps onto the scanner platform, and a click of the mouse starts the measuring process. The camera records the photogrammetric markings and transfers them to a PC in approximately 25 sec. The image-processing software delivers a precise, three-dimensional representation of the foot.

Thanks to its USB 2.0 connection, the uEye camera from IDS can be connected directly to a laptop or PC without requiring additional hardware. The high bus bandwidth allows a data transfer rate of up to 480 Mbps. If necessary, images from several cameras can be simultaneously recorded and displayed on the PC. The necessary power is also supplied through the Universal Serial Bus.

With a resolution of up to 3.1 megapixels, the uEye cameras can record up to 75 frames/sec in full mode. Higher frame rates are possible in "Area of Interest" (AOI) mode. Both monochrome and color cameras (using Bayer Mosaic color conversion) with rolling or global shutter are available, optionally supplied with or without memory. The cameras use CMOS sensors whose photo-sensitivity almost reaches that of CCD cameras. Functionalities such as windowing, binning, subsampling, and horizontal/vertical image mirroring are integrated. Resolution ranges from 640 x 480 pixels to 2,048 x 1,536 pixels, depending on the camera type. All models are equipped with a universal, optically decoupled trigger input and an optically decoupled output that can be used, for example, to activate a flash.

Dirk Rutschmann, CEO of corpus.e, explains why the company chose cameras by IDS: "Mobility, easy handling, and the cost factor of the device were what we focused on when we were developing the lightbeam 3D foot scanner. Based on the IDS industrial cameras, we are able to offer a solution that only costs a fifth of the price of conventional laser scanners to buy. They also eliminate the maintenance expense that the regular calibration laser scanners require."

Apart from the foot scanner and the MagicalSkin special stocking, all an orthopedic footwear specialist or shoemaker needs for onsite measuring is a PC. With a click of the mouse, the camera starts recording the 3D outline in a circular motion, so that heel, toes, and the arch of the foot are recorded simultaneously in a single scanning process. At a net weight of 16 kg (35 lb), the entire scanning unit, including base, is not only comparatively light, allowing for mobile use, but also small. The uEye VGA camera itself weighs practically nothing, due to its miniscule size (24 x 32 x 27.4 mm in standard housing without memory).

Because of this innovation, custom shoes for congenital foot problems or feet deformed by accident or illness will be faster and cheaper to manufacture and adapt to individual needs. And because every foot is an individual masterpiece of 28 bones, 19 muscles, and 107 tendons, many healthy feet will also be grateful for shoes with a perfect fit.

Freely accessible source code

All uEye cameras support the current Windows operating systems and Linux. A software development kit (SDK) with demo programs for image recording and analysis, and the source code for them, written in C/C++, are supplied free with each camera. Developers can adapt the source code to specific requirements or integrate it into programs of their own. Users can set all camera-specific parameters with the SDK. It additionally allows memory management using ring, buffer, and double-buffer management.

The Direct Draw Interface enables flicker-free insertion of individual information such as date, time, or images into live video. A TWAIN driver, an ActiveX component, and a WDM are available to users of standard software solutions. For popular machine vision programs, such as ActivVision Tools, Common Vision Blox, HALCON, or NeuroCheck, direct interfaces are available.

For more information, visit www.ids-imaging.com.

Published April 2012

Rate this article

View our terms of use and privacy policy